Your HVAC system is the heart and lungs of your cannabis grow facility. Unlike your home A/C unit, which cools for comfort, a commercial HVAC system for a grow room needs to control a variety of factors in a highly dynamic environment.

It’s never too early in the grow room design process to think about whether you’ve got the right size grow facility HVAC system. Ensuring you’ve got the right HVAC system will not only provide the vital inputs to compete in the high-end craft cannabis market, but also save you money in your monthly operating expenses.

What Is Right-Sizing?

Right-sizing a grow facility’s HVAC system is sort of like the story of Goldilocks: the HVAC system won’t be right if it’s too big or if it’s too small, and it may result in the grow room being too hot or too humid. Right-sizing means you’re balancing the capital costs with being able to maximize profits, reduce risk and optimize long-term savings in operating expenses, ensuring the system has enough capacity to manage your environment and meet your production goals without a sky-high electricity bill.

What Factors Do You Need to Consider for Your Grow Facility HVAC Needs?

Your commercial grow room is a complex environment, playing host to many living organisms — including plants, people and both bad and good microbes — as well as many processes that are constantly adding or removing energy from the overall ecosystem. Your HVAC system for your grow facility needs to be able to handle it all.

Here’s what you need to consider when determining the right size system for your business.

1. Energy Balance

The first law of thermodynamics states that energy cannot be created or destroyed, only transferred from one form to another. In practical terms, this means that the energy that is put into a grow room needs to be removed. Grow rooms receive two main sources of energy:

- Electricity powers lights which in turn puts off photons and heat. Plants need energy in the form of light to grow and thrive. That energy can come from lights or the sun, but that energy is not created equally. For example, LED lights are more energy-efficient energy efficient than other artificial light sources, meaning they’ll create less heat — and that means your HVAC system has to remove less heat.

- Water transports nutrients through a plant and gives it turgor. Almost all of the water you give to a plant’s roots comes out as water vapor from the stomata via transpiration.

Of course, all the other equipment you’re running inside your grow facility will be generating heat, as well as your employees. Understanding how much energy will be in the system is key to knowing how much capacity your HVAC system needs to balance the equation

2. Water

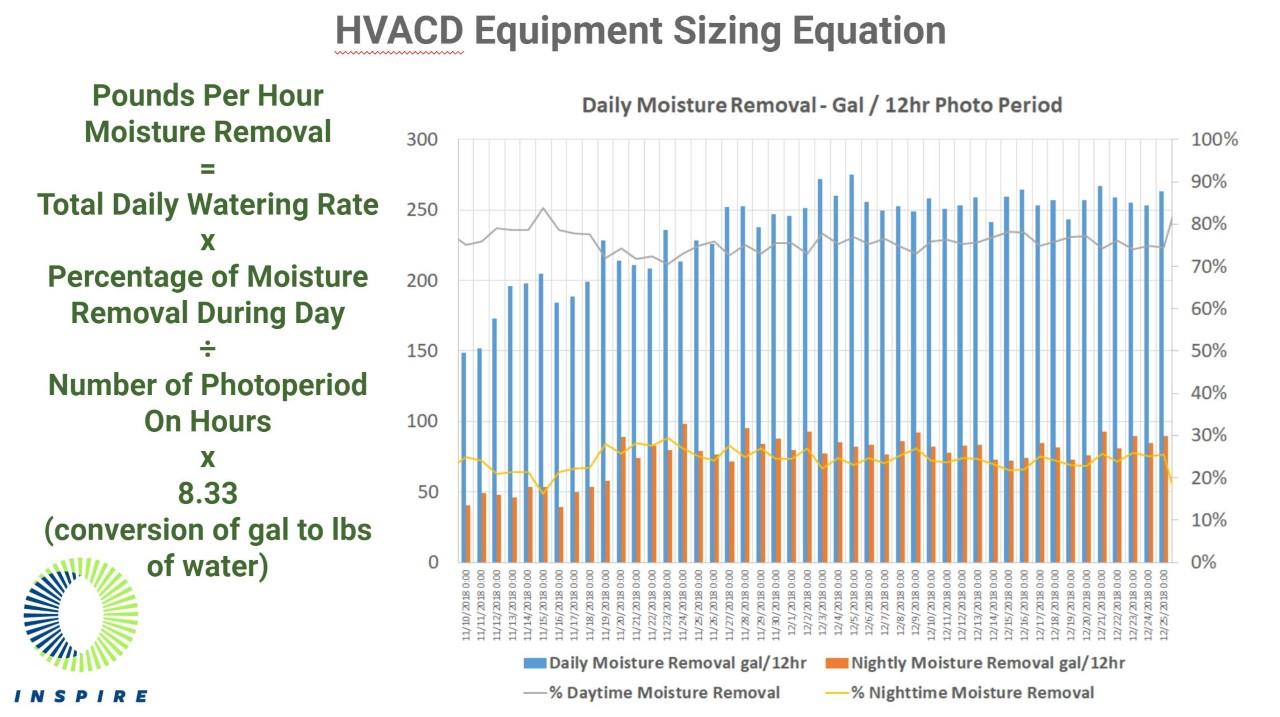

Water, like light, is critical to the health and prosperity of your cannabis plants. But water in the wrong places or the wrong amounts can do more harm than good. As plants undergo photosynthesis to grow, water is one of the byproducts. As the plants grow and add biomass, the more humidity that will be created by the plants. Understanding the amount of water your integrated HVAC system can remove from the atmosphere is critical.

3. Plant Density

As mentioned above, the density of your canopy can determine how much capacity your grow facility HVAC system needs. In particular, a dense canopy, when paired with undersized or poorly circulating systems, can create microclimates that feature higher temperatures or relative humidity. An inconsistent environment can equal an inconsistent product in the end in the best case and complete loss of crop in the worst case.

4. Layout

Your commercial grow room design plans need to incorporate an HVAC system that will be able to deliver a unique, consistent temperature and humidity level for each room in your facility. A right-sized HVAC system doesn’t just mean you’ve got the right load capacity, but also that you’ve got the right ductwork and in-room airflow layout to deliver air and remove moisture from the right spots. A well-designed system can help ensure microclimates are eliminated.

5. Future Phases

Lastly, right-size doesn’t just mean for right-now. Look to the future and ask yourself whether you are planning to add more plants/vertical tiers or make other changes to your grow room facility. It’s always good to get expert grow room HVAC advice to help you plan accordingly and be ready for future phases when it is the most cost-effective. That way, you’ve got room to grow while still minimizing capital and operating expenses today.

Why Right-Sizing is Key to Your Bottom Line

An HVAC system is one of the most important purchases you will make for the success of your crops – and therefore your business. But an HVAC system for a commercial grow room doesn’t have to be exorbitantly expensive to be the right size for your business. The right one will optimize plant growth, health and vitality without waste. It will also ensure your plants have the best environment to maximize yield, while reducing the risk to your plants that can be created with under-performing HVAC systems like humidity spikes when the lights turn off.

We’ve spent years helping develop commercial grow room design plans that incorporate integrated HVAC solutions that independently control temperature and relative humidity all with the goal of maximizing plant vitality. As the regulated cannabis industry finds its footing, InSpire is helping companies discover their right-size HVAC system so they can mitigate risk of crop loss and drive financial impact. Let us know how we can assist you, too!