When you combine the costs of new construction or retrofitting a commercial cannabis grow room with everyday operating expenses, it’s critical for you to maximize every crop cycle. Even if you start off with excellent genetics, a poorly designed grow room can result in lower quality flower that doesn’t pass testing or even worse: crop loss.

When building a commercial grow room, you have to think about it for what it is: a complex, living ecosystem. Expert commercial grow room builders know that precision cannabis climate control hinges on the fact that the grow room environment is constantly changing as plants grow bigger, people come and go, and the temperature and relative humidity rises and falls. Whereas outdoor grows are susceptible to the whims of the environment, indoor grow rooms allow us to bring a new level of control to the environment, turning a seasonal harvest into a year-round crop. However, this is only possible if you have the right systems to keep things under control.

Here are five tips to help you build and maintain a commercial grow room that ensures you can maximize yields from season to season.

1. Design your grow room correctly from the start

Whether a new build or a retrofit, the best commercial grow room design plans balance upfront costs and long-term operating expenses. One of the hardest parts about designing a successful grow room from the start is understanding how each aspect of your environmental equipment impacts the performance of the others.

For example, the lighting system you end up choosing can dramatically alter the amount of heat being generated in the grow room (and the amount of electricity you’re using.) Whether you choose HID or LED lights can significantly change the amount of air conditioning capacity you need to displace that heat. Lighting choices are also a big factor in how the vapor-pressure deficit (VPD) chart for your grow rooms is drawn.

That leads us to our second point…

2. Get the right size HVAC system for your cannabis grow facility

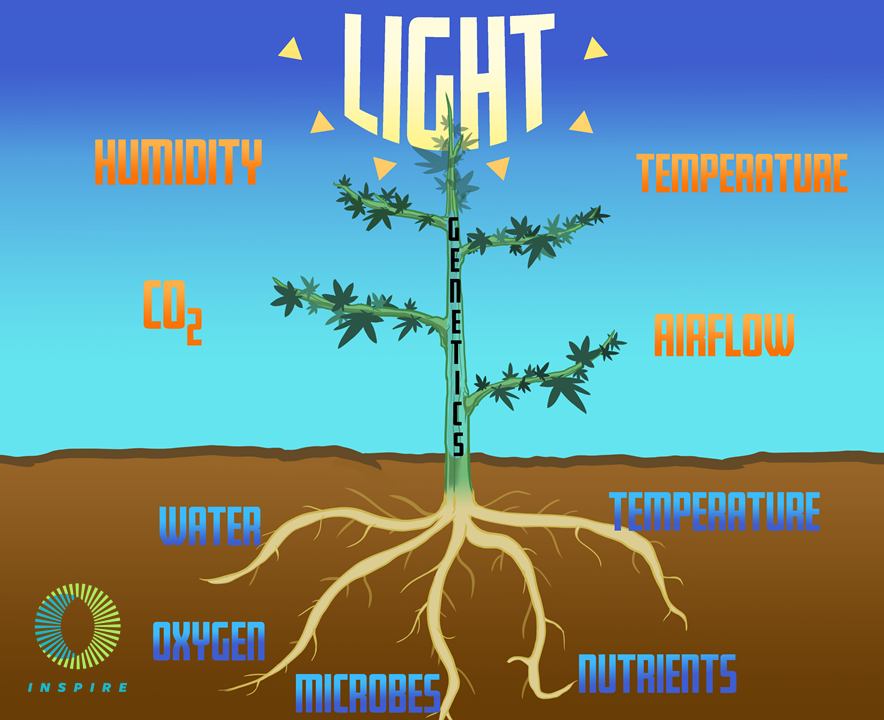

Your commercial grow room’s HVAC system is directly responsible for 4 of the 9 cardinal parameters of your grow room and indirectly responsible for the other 5. Ideally, it remove humidity from the air that plants transpire, keep the temperature at the right level, and circulate air evenly to eliminate microclimates. Your HVAC system plays a big role in the success of your grow, so getting it right the first time is of paramount importance. High-performing systems can also provide biosecurity measures by removing pests and pathogens, enriching the air with CO2, removing odors, provide CO2 life-safety purging and providing room pressure control.

Remember, HVAC systems aren’t one size fits all — what you have done in the past may not be the right system now. Something as simple as adding extra plants to your grow room can change your HVAC needs. Trust a professional to help you find the right balance between upfront investment and minimizing operating expenses to meet your production goals. More on right-sizing your HVAC can be found here: https://inspire.ag/2020/05/06/importance-of-right-sizing-your-hvac/.

3. Maintain an environment attuned for each stage of the plant life cycle

Odds are that you’re building a commercial grow room alongside rooms for other stages of the plant life cycle. As we’ve covered in more detail in our blog post on temperature and humidity settings by grow room type, required temperatures can range between 65 and 85 degrees and relative humidity can go from 90% in the propagation rooms to 50% in the flower rooms to 45% in the drying rooms. That level of variability requires an integrated HVAC system that manages temperature and humidity levels in tandem.

The other part of this is being able to monitor and control the environment at each stage of the plant life cycle. With state-of-the-art grow room controllers you can adjust temperature and humidity from anywhere in the world on the fly. With a single dashboard, you’ve got insight into the overall health of your environment and the ability to manage every aspect of it.

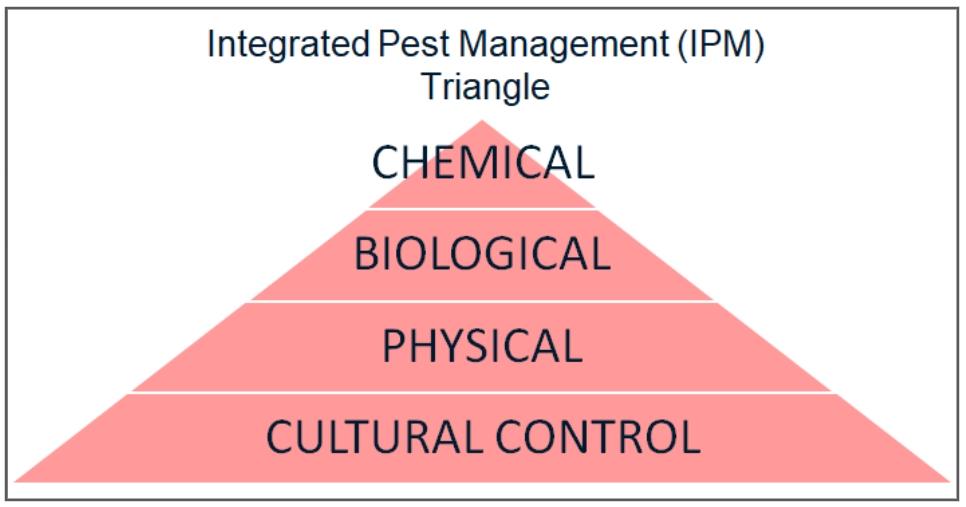

4. Minimize biosecurity risks

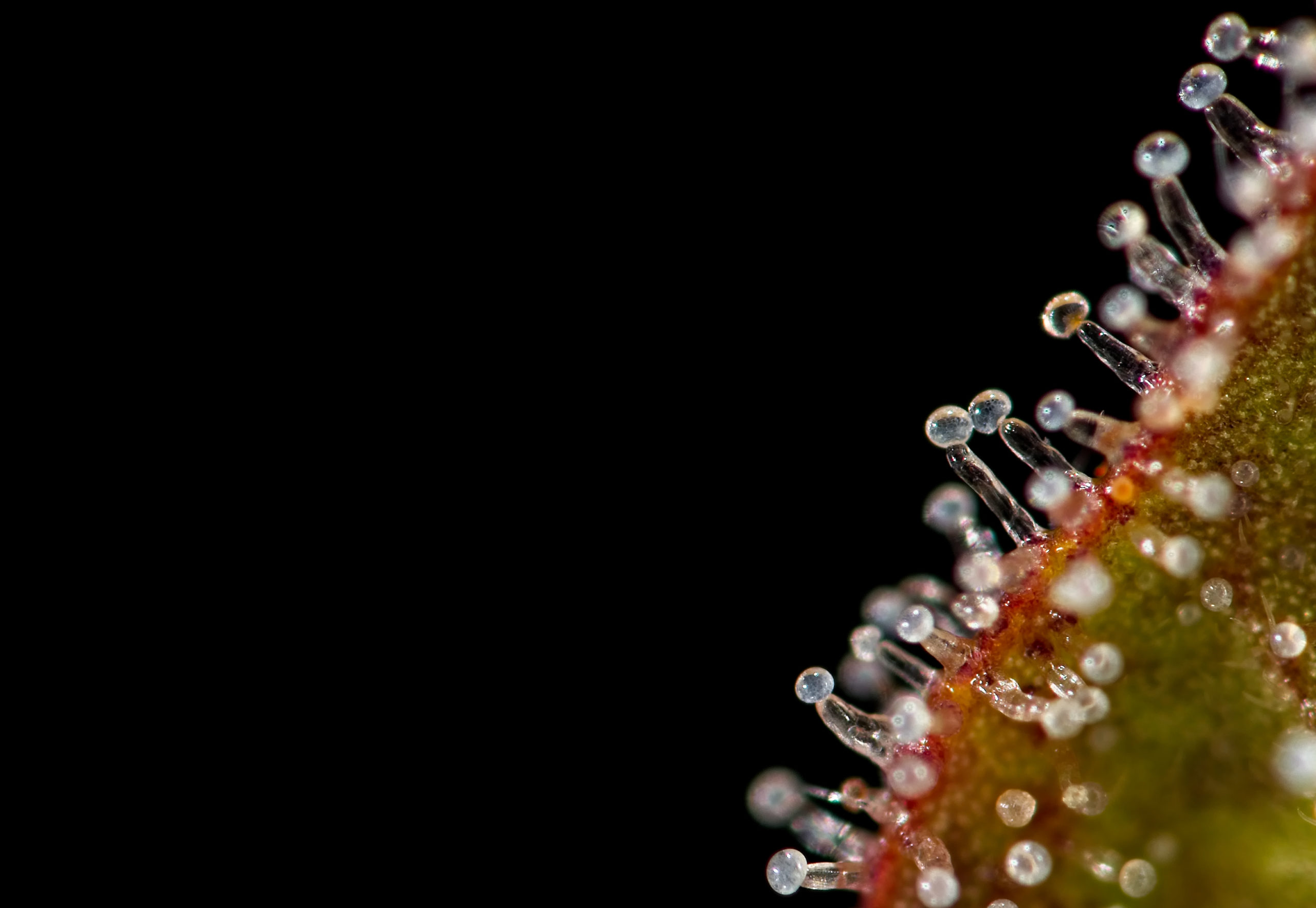

When it comes to building a commercial grow room designed to maximize yields, biosecurity is a critical factor. As a matter of fact, cultural control is the foundation of an effective integrated pest management (IPM) program. From the invisible bacteria and mold that can quickly take hold to the damage that can be wrought by an infestation, there are many factors that can damage crop yield.

Prevention should be the goal, rather than containment. The key to this is keeping a clean environment. This includes ensuring that humidity levels are correct, including that standing water is removed. Furthermore, having the right filtration on your HVAC system can keep any microscopic pathogens from spreading.

5. Choose the right partner to help you maintain operational efficiency

Once you’re done building your commercial grow room, that doesn’t mean the work of maximizing yields is done. Cultural control, constant commissioning and monitoring of the HVAC system performance and ongoing cannabis facility maintenance, as well as evaluating the environment based on the cultivars you’re growing each season, make choosing the right partner critical to your success.

There are few companies that have expertise in both HVAC and cannabis, but InSpire’s unique background and experience in the cannabis industry make us a great partner to help design your grow room. We’ve been working to establish cannabis HVAC best practices for companies that will one day make up the Good Manufacturing Practices for the industry.

Contact us today and see how we can help you design a commercial grow room HVAC system to maximize your yields.